nature of the silico manganese slag

ReviewA review on characteristics of silico-manganese slag and its

2022.1.1 Silico-manganese slag is a byproduct of silico-manganese alloy production, and its major oxide components are SiO 2, CaO, Al 2 O 3, and MnO. It's chemical composition similar to blast furnace slag, except it is more acidic due to higher SiO 2 and

Charlar en Línea

A review on characteristics of silico-manganese slag and its ...

2022.1.1 A review on characteristics of silico-manganese slag and its utilization into construction materials. S. Nath, N. Randhawa, Sanjay Kumar. Published in Resources,

Charlar en Línea

Evaluation of the suitability of ground granulated silico

2016.10.30 Granulated silico-manganese slag (GSS), a by-product of ferro-alloy production, has been used to replace granulated blast furnace slag (GBFS) in Portland

Charlar en Línea

(PDF) Physicochemical Characteristics of Silico

2022.5.18 Silico Manganese (SiMn) slag is a by-product of ferromanganese and silicomanganese alloy production. The large quantities of these slags have caused several challenges in disposing of

Charlar en Línea

Properties of silicon manganese slag as an aggregate for

2020.3.4 SiMn slag, a nonferrous metal, is generated in the smelting of SiMn, and has a high Si-based oxide content and low Fe-based oxide content. Frias et al. reported

Charlar en Línea

Silicomanganese slag: Hydration mechanism and leaching

2022.4.4 Silicomanganese slag (SMS) is a by-product discharged in the process of SiMn alloy production. About 1.2–1.4 tons of SMS are produced when producing one ton

Charlar en Línea

Influence of Granulated Silico-Manganese Slag on Compressive

2018.1.30 The nature of this slag is silico-calcic similar to blast furnace slag, mapped in ternary diagram (Fig. 1). The main compositional difference is significantly

Charlar en Línea

Silicomanganese slag: Hydration mechanism and leaching

2022.4.4 Silicomanganese slag: Hydration mechanism and leaching behavior of heavy metal ions - ScienceDirect Article preview Abstract Introduction Section snippets

Charlar en Línea

Behavior of Slag in Ferromanganese and Silicomanganese

2021.6.29 Because of ionic nature of slag, the distribution of Mn and Si incurs exchange of electron between reacting species. As Mn and Si are in different valance

Charlar en Línea

Silicomanganese slag: Hydration mechanism and leaching

2022.4.1 Silicomanganese slag: Hydration mechanism and leaching behavior of heavy metal ions Semantic Scholar. DOI: 10.1016/j.conbuildmat.2022.126857. Corpus

Charlar en Línea

(PDF) Physicochemical Characteristics of Silico

2022.5.18 Silico Manganese (SiMn) slag is a by-product of ferromanganese and silicomanganese alloy production. ... and brittle nature, e nabling the slag to be ground more e ciently with less e nergy

Charlar en Línea

Silicomanganese slag: Hydration mechanism and leaching

2022.4.4 Hydration activity and heavy metal ions leaching behaviors should be considered simultaneously when metallurgy slags were utilized as SCMs. Silicomanganese slag (SMS) is a by-product discharged in the process of SiMn alloy production. About 1.2–1.4 tons of SMS are produced when producing one ton of SiMn alloy [8], [9], [10], it

Charlar en Línea

Impact of Slag Content and Curing Methods on the Strength of

2019.8.7 In the reported study, the effect of slag content and curing methods on the strength development of alkaline activated (AA) silico-manganese fume (SiMnF (S)) and ground granulated blast furnace slag (GBSF (G)) blended mortar using NaOHaq and Na2SiO3aq was studied. The mixtures were prepared with 100% SiMnF (AAS100G0),

Charlar en Línea

Influence of Granulated Silico-Manganese Slag on Compressive

2018.1.30 Silico-manganese slag, ferrochrome slag, zinc slag, nickel slag, lead slag, and red mud are notable among them [18,19,20,21,22,23]. Fly ash, a byproduct of thermal power plant, is most widely explored material for geopolymer synthesis due to its easy availability, suitable chemical composition, glassy content, powdery nature, and

Charlar en Línea

ScienceDirect - Development of alkali activated cement from ...

2013.7.1 Silico-manganese (SiMn) slag has been used to develop alkali activated cement binder. The reactivity of SiMn slag was altered by mechanical activation using eccentric vibratory and attrition mill. The reaction kinetics during alkali activation of SiMn slag and structural reorganization were studied using isothermal conduction calorimetry

Charlar en Línea

A review on characteristics of silico-manganese slag and its ...

2022.1.1 Silico-manganese slag is a byproduct of silico-manganese alloy production, and its major oxide components are SiO 2, CaO, Al 2 O 3, and MnO. It's chemical composition similar to blast furnace slag, except it is more acidic due to higher SiO 2 and lower Cao and also contains ∼10 wt.% MnO.

Charlar en Línea

Manganese Slag - an overview ScienceDirect Topics

11.4.5 Manganese and silico-manganese slag. ... The sources vary widely in nature, including shredded tires, solvents, water treatment plant sludge and used oil, among others (Pontikes and Snellings, 2014). Another avenue for manufacturing eco-efficient cements is the development of new materials wholly different from ordinary Portland cement.

Charlar en Línea

Silicomanganese slag: Hydration mechanism and leaching

2022.4.1 DOI: 10.1016/j.conbuildmat.2022.126857 Corpus ID: 246937700; Silicomanganese slag: Hydration mechanism and leaching behavior of heavy metal ions @article{Liu2022SilicomanganeseSH, title={Silicomanganese slag: Hydration mechanism and leaching behavior of heavy metal ions}, author={Qiang Liu and Jun Li and

Charlar en Línea

STRENGTH AND COMPRESSIBILITY CHARACTERISTICS OF SILICO MANAGANESE SLAG

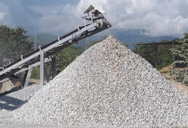

Silico Manganese Slag is light weight material compared to conventional fill material (Sand and Moorum ) by about 35-45%. The light weight of the material is advantageous in construction of embankments on weak subgrades. Silico Manganese Slag is coarse grained material with no fines and has good frictional characteristics

Charlar en Línea

Kinetic Modeling of the Silicothermic Reduction of Manganese

2018.11.8 A model was developed to describe the mixed rate control kinetics in systems with MnO-SiO2-CaO-Al2O3 slags and Fe-Si metal droplets. During the reaction of Fe-Si droplets and slag, Mn2+ transport was found to be part of controlling the system but could not sufficiently describe all initial conditions (chiefly, changes to initial silicon

Charlar en Línea

Nature Of The Silico Manganese Slag-HXJQ Crusher Machine

Silico manganese is an alloy with 60% to 68% manganese, 14% to 21% silicon , and 5% to 2.5% carbon. It is produced by smelting of slag from high-carbon Ferro Manganese or of Manganese ore with coke and a quartz flux in a submerged electric arc furnace.the process requires power consumption of about 3, 800 to 4, 800

Charlar en Línea

Evaluation of the suitability of ground granulated silico-manganese ...

2016.10.30 Silicomanganese slag is generated in the production of ferroalloys with a high MnO content by carbothermic reduction, generally in submerged arc furnaces. Regarding its chemical composition, silicomanganese slag is richer in SiO2 and has less CaO than GGBFS, but the composition (overall) is similar, so it can be expected to have

Charlar en Línea

Influence of Granulated Silico-Manganese Slag on

2019.7.1 Silico Manganese (SiMn) slag is a by-product of ferromanganese and silicomanganese alloy production. The large quantities of these slags have caused several challenges in disposing of

Charlar en Línea

Ferroalloy Refining Process SpringerLink

2023.6.13 The silico-manganese alloy becomes low-silicon silico-manganese alloy, which is charged into the refining electric furnace. An excessive amount of manganese ore and lime are added to continue desiliconization and refining. The medium/low-carbon ferromanganese and high-manganese slag will be generated during this stage.

Charlar en Línea

Evaluation of the suitability of ground granulated silico-manganese ...

2016.10.30 Granulated silico-manganese slag (GSS), a by-product of ferro-alloy production, has been used to replace granulated blast ... Si/Al ratio etc.) is evident from EDX analysis. This change is associated with the change in the slag nature and reaction kinetics. The following points are deduced from EDX analysis. 1. The Ca/Si ratio ...

Charlar en Línea

Slags in Production of Manganese Alloys - Wiley Online Library

2013.3.6 The paper analyses the equilibrium partitioning of manganese and silicon between slag and alloy during the production of high carbon ferromanganese (HC FeMn) and silicomanganese (SiMn) using FACTSage software. The results of this modeling are compared with industrial and experimental data and used to elucidate the nature of the

Charlar en Línea

Recycling Construction Material: A Systematic Review

Silico Manganese (SiMn) slag is a by-product of ferromanganese and silicomanganese alloy production. The large quantities of these slags have caused several challenges in disposing of them without ...

Charlar en Línea

Sustainability Free Full-Text Re-Use of Silico-Manganese Slag

2021.10.25 The world’s rapidly growing demand for raw manganese has made it increasingly important to develop methods for the economic recovery of manganese from secondary sources. The current study aims to present possible ways for the recycling and reuse of silico-manganese slag landfilled in Tulcea, City on the Danube River close to

Charlar en Línea

Production of Ferro- Manganese – IspatGuru

2018.6.19 Ferro-manganese (Fe-Mn) is an important additive used as a deoxidizer in the production of steel. It is a master alloy of iron (Fe) and manganese (Mn) with a minimum Mn content of 65 %, and maximum Mn content of 95 %. It is produced by heating a mixture of the oxides of Mn (MnO2) and iron (Fe2O3) with carbon (C) normally as coke or coal.

Charlar en Línea

A Study on the Impact of Silicon and Manganese on Peritectic

2023.3.31 The ferrite potential and compositions of carbon equivalent for C A and C P are well-known for plain carbon steels and the nature of the peritectic transformation in such steels are already well-documented. For instance, the carbon content at the lower boundary of the peritectic—C A and peritectic point—C P have already been thermodynamically

Charlar en Línea

- hammer mill for sale in south africa plant

- molino pulverizador de suspensión de alta presión ygm

- minério de ferro triturador grizzly

- talleres para molinos de carne

- canteras de piedra en tandil

- El mineral de hierro equipos de separación magnética

- Waste Treatment Hospital

- moinho de moer gr227o lugar do real argela

- trituradora de piedra michigan

- a hacer que el molino de carbón

- Productividad Minera

- y venta de maquinas seleccionadoras de aridos en argentina

- grinding mill in calcite powder processing in turkey

- diagramas de flujo de compras

- En Exhibición Productos