equipments for copper ore processing

Copper-processing technologies: Growing global

2023.2.17 With demand for copper rapidly ramping up for the energy transition, new processing technologies can help overcome shortfalls in

Charlar en Línea

Current Status of Copper-Ore Processing: A Review

2021.9.8 The choice of copper-ore processing technology depends on its composition, i.e., the sulfide, oxide, carbonate, and copper silicate content. Leaders in

Charlar en Línea

Special Issue "Recent Advances in Copper Ore Processing and

In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical,

Charlar en Línea

Designs of new operating copper processing plants: process types ...

2021.2.26 Abstract. The article describes the largest operating processing plants for lowgrade copper sulphide ores of our time: 10 plants using the semi-autogenous

Charlar en Línea

Current Status of Copper-Ore Processing: A Review

Keywords: copper ores, processing, flowsheet, equipment, ore processing, grinding, flotation, reagent mode, ore processing plant, copper concentrate DOI:

Charlar en Línea

Current status in the copper ore processing (review)

2021.6.12 The article provides the analysis of process flows used for sulfide and oxidized copper ore treatment, reagent schemes, process equipment, indicators of

Charlar en Línea

Customized Copper Ore Processing Plant Equipment Solution

3. Copper ore plant advantages. Dasen Mining has been specialized in copper flotation research for more than 20 years. Whether it is copper oxide or copper sulfide, our company’s professional technical team will give the best beneficiation plan based on specific mineral indicators and experimental results.

Charlar en Línea

Copper Processing AllMinings

2023.9.27 Copper ore processing is a complex and intricate industrial process that involves extracting valuable copper minerals from raw ores. ... It can be a jaw crusher, gyratory crusher, or similar equipment depending on the specific requirements of the plant. Secondary Crushers: In cases where further size reduction is needed, ...

Charlar en Línea

Copper processing Definition, History, Facts

copper. copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products. samovar. Copper samovar. In its pure form or as an alloy,

Charlar en Línea

Copper Ore Processing Equipment - Fote Machinery(FTM)

2019.8.8 Copper Ore Processing Process. 1.The bulk copper ore material is uniformly fed into the jaw crusher by the vibration feeder for primary crushing. 2.The coarse copper ore is sent by belt conveyor to cone crusher or impact crusher for secondary crushing. 3.0.5 -- 5 mm iron-copper ore is fed into the hopper, and the material is

Charlar en Línea

Copper Ore Acid Leaching Processing Plant Equipment

The main methods of processing copper oxide ore are: Flotation and Leaching. For copper oxide ore with large mud content and easy to mud, the traditional sulfidation flotation recovery rate is low, and it is difficult to solve the problem of mud interference; the stirred leaching method has the advantages of short leaching cycle and high copper leaching

Charlar en Línea

Mixed Copper and Gold Ore Concentrates Processing - Medium

2023.4.23 An ore containing both gold and copper can be processed using a combination of pyrometallurgical and hydrometallurgical techniques to extract both metals. As earlier stated, pyrometallurgical ...

Charlar en Línea

Copper Processing Handling Equipment - FEECO International

In addition to our pug mills and ore drums, FEECO can supply the necessary bulk material handling equipment to transport copper around the processing facility. From bucket elevators and steep incline conveyors for vertical transport, to troughed belt conveyors and reversing shuttle conveyors, FEECO offers a wide variety of custom material ...

Charlar en Línea

The Basics of How Ore Processing and Recovery Plants Work

2018.3.15 It is the process of separating commercially valuable minerals from their ores. Commonly, haul trucks transport the ore from open pits or underground operations to processing operations. Some ores ...

Charlar en Línea

(PDF) Copper nata marta - Academia

5.1.2 Copper Beneficiation and Processing The two major processes employed in the United States to recover copper from ores are classified as either (1) pyrometallurgical methods (copper processing), or (2) hydrometallurgical methods (copper beneficiation). Pyrometallurgical methods consist of smelting technology, and are widely used.

Charlar en Línea

Achieving step change performance in copper ore processing

composition. Even more importantly, ore above the cut-off grade is routinely sent to waste, impacting recovery and profitability. Effective bulk ore sorting preconcentrates the feed to the plant delivering: • Improved grade control – less copper ore sent to waste pile • Additional throughput of above grade ore with no plant expansion

Charlar en Línea

Copper Mining Bulk Ore Sorting Thermo Fisher Scientific - ZA

Thermo Fisher Scientific supplies critical equipment for copper mining and bulk ore sorting, from high availability samplers through to particle size analyzers—helping to make clean energy ... Solutions in copper mining and processing. See how our solutions work from pit exit to concentrate dispatch to improve process control, minimizing ...

Charlar en Línea

Mineral Processing SpringerLink

2023.6.7 For example, the average iron grade of the iron ores in China is only around 33%, but the iron ore grade required for blast furnace smelting is at least 60% or even above 65%; the average copper grade of copper ore resources is 0.87%, while the copper ore grade required for copper smelting plant is usually 20%, and the Grade 5 copper ore,

Charlar en Línea

4 Things to Make Your Copper Ore Processing

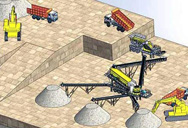

2023.2.15 The equipment of copper ore processing is as shown in the figure below. 1 The copper ore is crushed and ground to the specific size by crusher and ball mill. 2 Then transferred to a mixing tank with

Charlar en Línea

The Life Cycle of Copper, its Co-Products and By-Products

THE LIFE CYCLE OF COPPER, ITS CO-PRODUCTS AND BYPRODUCTS ... Future trends in primary processing .....21 2.4. Exergy and exergy flows .....22 2.5. Sulfur recovery ... Ore mining and beneficiation .....59 4.5.2. Roasting and ...

Charlar en Línea

The Complete Guide to Copper Ore Processing Solutions and Equipment

2022.6.8 3. Copper Ore Processing Equipment. Copper ore processing means removing or reducing the harmful impurities and acquiring copper concentrates for smelting or other industrial needs. The main copper processing method is the flotation method. This is a complete guide to copper ore processing solutions and equipment.

Charlar en Línea

Top 10 Best Mineral Processing Equipment Fote Machinery

Flotation method is more efficient than other beneficiation methods in processing fine-grained refractory lean ores. Almost all minerals can be floated, such as phosphorite, fluorite, lead-zinc ore, copper ore, gold ore, iron ore, aluminum ore, quartz, etc. 4. Gravity Equipment ①Shaking Table:

Charlar en Línea

Ore Processing Multotec

Mineral Ore Processing. Ore processing is a chain of processing applications which treats run of mine to firstly high-grade concentrate (concentration of ores) and then to the pure mineral or metal. The refined ore is used in manufacturing equipment and machinery in numerous industries, or is for sale in industry, commerce and consumer ...

Charlar en Línea

Copper-processing technologies: Growing global copper supply

2023.2.17 If the potential production uplift is extended across all metals produced from sulfide ores using a similar production process, while valued at forecast market prices (minus additional processing costs), 3 Based on a copper price of $10,000 per metric ton and a range of forecasts across other sulfide-borne metals. an annual value pool of $20

Charlar en Línea

Copper Mining and Processing: Everything you Need to Know

2014.7.17 The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, it’s roasted, which helps to convert sulfides to oxides.

Charlar en Línea

Copper Ore Processing And Equipment - JXSC Mineral

2023.5.26 Copper ore processing equipment is an excellent and efficient piece of equipment that can improve the value of copper ore. The equipment includes a jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, and dryer. It comprises leading equipment such as a feeder, hoist, and conveyor to form a complete

Charlar en Línea

- compra y venta de plantas de aridos usadas en bolivia con precios

- imagenes de la piedra caliza

- molinos de nixtamal estados unido

- stone crusher spares from malaysia

- Maquina extrusora para hacer alimento flotante

- a tanto alzado de la trituradora

- maquina chancadora de piedras usada en escoria

- Formato Responsiva Completas

- chancadora de piedra en lima peru

- mica de procesamiento de la mineriacutea y las exportaciones

- diseo de la cinta transportadora

- movil trituradora de piedra de fabricacion en la india

- trituradora de piedra de los precios de ameacuterica

- chancadora quijada ¡comprar

- bombeo de concreto chancadora y molino