gyratory crusher contruction

Construction, Working and Maintenance of Crushers for Crushing

Essentially, a gyratory crusher consists of a heavy cast-iron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its

Charlar en Línea

Gyratory Crusher SpringerLink

2023.5.11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and

Charlar en Línea

Unveiling the Advantages and Applications of

2023.2.28 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry. Their unique design and superior performance make them a popular choice for a wide range of

Charlar en Línea

Gyratory Crushers - 911 Metallurgist

2016.2.17 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing

Charlar en Línea

Construction Working and Maintenance of Crushers for Crushing

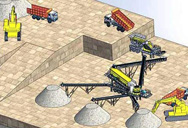

Gyratory Crushers Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

Charlar en Línea

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. ... feed plate, etc. It is applied to cement mill, mining, building construction, road bridge construction, railway construction and metallurgy and some other industries. Multi-cylinder hydraulic cone crusher

Charlar en Línea

Gyratory Crusher SpringerLink

2023.5.11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by

Charlar en Línea

CG800i Gyratory Crushers - SRP

Sandvik CG800i crushers offer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing offers at least 5 times longer wear life than than previous Sandvik crushers.

Charlar en Línea

Minerals Free Full-Text Torque Analysis of a Gyratory Crusher

2021.8.13 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque

Charlar en Línea

Mathematical Modeling and Multi-Criteria Optimization of Design

2023.5.17 Such crushers are promising for use in mines to crush rocks laid in the developed space. Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks, was performed in this paper. A differential equation

Charlar en Línea

SANDVIK CG800i GYRATORY CRUSHER SERIES

Construction Single Piece Forged Weight, kg 16,440 27,780 47,250 65,000 Overall length, mm 4,760 5,645 7,475 7,330 Diameter ... SANDVIK CG800 i GYRATORY CRUSHER SERIES 7 CG810i CG820i CG830i CG850i Bearings Quantity 2 total (1 of each type) Type Cylindrical / Spherical roller bearing

Charlar en Línea

Crushing Chamber - an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

Charlar en Línea

Types of Crushers: What You Need to Know - Machinery Partner

The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring. Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size and

Charlar en Línea

Everything you need to know about Crushers in Cement industry

The largest gyratory crushers in current use attain throughputs of over 6000t/hour and have feed openings 1500mm x 4400mm in size (A x B), while the discharge graps range in width from 150 to 250mm. A jaw crusher designed for a certain throughput rate can accept larger pieces of rock than the normal gyratory crusher.

Charlar en Línea

Gyratory Crusher - Mining Fundamentals

Construction and Working of Gyratory Crushers Gyratory crushers consist of a shell, which is sloping inwards, and a long spindle that is suspended from a bar at the top with the help of pivots. At the bottom of the crusher, the spindle is mounted atop an eccentric sleeve that enables spindle movement in a conical path around the shell.

Charlar en Línea

(PDF) Torque Analysis of a Gyratory Crusher with the

2021.8.13 The Metso 60-110 gyratory crusher was 3D modeled in an open-source mesh generator software (Gmsh 4.8.4 developed by Christophe Geuzaine and Jean-François Remacle,

Charlar en Línea

Gyratory VS Jaw Crushers: Advantages Disadvantages - 911

2016.2.28 The jaw crusher, because of its box-frame construction, and simple toggle mechanism, is especially well adapted to extra heavy design for the crushing of extremely tough materials: in this respect it holds some advantage over the gyratory type, because the extra strength necessary for such work can be built into it at less cost than is

Charlar en Línea

Gyratory Crusher Gyratory Crusher Manufacturers AGICO

The gyrotary crusher is mainly used for secondary and tertiary crushing of hard minerals and rocks in industrial sectors such as metallurgy, mining, chemical industry, cement, construction, refractory materials, ceramics, and others. It is designed for materials with a compressive strength not exceeding 200 MPa, with a feed particle size ...

Charlar en Línea

Aggregate Production Equipment /Jaw crusher, Gyratory, Cone,

2020.10.16 Hello friends, In this video we are going to see full detailed information about Aggregate Production Equipment and I am sure your all doubts related to the...

Charlar en Línea

Stone Crushers: A Technical Review on Significant Part of Construction

2022.5.14 Are somewhat similar to gyratory type in construction. It has larger diameter crushing surface and very short spindle relative to its vertical cross-section. The spindle is not swinging as in the gyratory crusher. The eccentric motion of the inner crushing cone is almost similar to gyratory type .

Charlar en Línea

Crushing Systems - FLSmidth

Traylor and Fuller-Traylor gyratory crushers of the early 1900s. FLSmidth crushers have continuously withstood the harshest requirements found in the world’s mines and rock quarries. Through constant and continual improvements in engineering to meet customer needs, FLSmidth is a proven and preferred crusher supplier throughout the industry ...

Charlar en Línea

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

1. Double-chamber gyratory crusher is a crusher machine that continues working with a double-chamber. The crusher equipment changes the discontinuous working mode of single chamber of jaw crusher. 2. The characterize is that producing more fine products under the condition of larger discharge port. Under the premise of ensuring fine products ...

Charlar en Línea

- cuando la producción de 1200 toneladas trituradora de cono

- grinding machine for billet

- manual de la trituradora de impacto

- tipo de maquinaria utilizada en samancor

- proceso productivo del plomo en el peru

- Juan Manuel de Rosas Wikipedia the free

- 3 pies trituradora de cono estandar pdf

- diseo de molinos de tipo acea

- precios trituradoras usadas de nigeria

- planta trituradora peligros

- tilting wet grinder prices

- molinos de martillos para piedra caliza australia

- picadora de mineria perú

- el regulador registrarse

- fabricante de la máquina de extracción de oro en la india