Power Consumption For Crushing Plants

(PDF) Optimization Capabilities for Crushing Plants - ResearchGate

2022.4.26 The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for

Charlar en Línea

Crusher Operating Costs: How to Optimize and Reduce

2016.1.10 It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant,

Charlar en Línea

Aggregate Production Optimization in a Stone-Crushing Plant

2020.2.8 Article 25 October 2019 1 Introduction The crushing of stones and other particles has many critical applications, such as the coarse crushing of ore meal and

Charlar en Línea

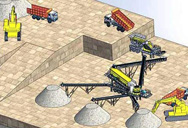

My Plant Planner - Metso

Launch My Plant Planner. Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance. My Plant Planner is packed full of unique features

Charlar en Línea

Crushing Plant - an overview ScienceDirect Topics

7.1 A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

Charlar en Línea

Modeling and Improving the Efficiency of Crushing

2023.5.16 More than 3 billion tonnes of raw materials are crushed every year. More than 70 billion kWh of electricity is consumed, representing up to 5% of the country’s total production. For a single

Charlar en Línea

Crushing Energy Efficiency - North American Mining Magazine

2021.6.10 According to one estimate, the mining industry consumes 12EJ per year of energy – or 3.5% of total final global energy consumption.1 The energy intensity of

Charlar en Línea

Crushing Energy Work of Crushing Machines - 911 Metallurgist

2016.3.5 Crushing Energy Work of Crushing Machines. A general awakening of interest among mill men concerning the mechanical efficiencies of their crushing

Charlar en Línea

(PDF) Analysis of Energy Consumption of Crushing

2017.1.27 Due to the inefficiency of the jaw crushing machine, whose no-load power consumption is between 40 and 50% of its rated power, the optimal switching control technique is shown to be a better ...

Charlar en Línea

China's soybean demand in Q4 set to slacken as crushers face power

2021.9.24 Soybeans crushing output till the end of Chinese Golden week Oct. 7, is expected to be sharply reduced amid widespread power cuts, a market source said. Typically, power consumption in China spikes in the last quarter every year. So, frequent power rationing is likely to markedly impact crushing operations in coming months as well.

Charlar en Línea

Performance optimization of an industrial ball mill for ... - SciELO

Power consumption of the grinding mill The power consumption of the grinding mill is a critical parameter in the economics of the chromite beneficiation process. The ball mill consumes about 25-30% of the total energy in the beneficiation plant, and hence any improvement will improve the overall economics of the plant.

Charlar en Línea

Crushing Energy Efficiency - North American Mining Magazine

2021.6.10 According to one estimate, the mining industry consumes 12EJ per year of energy – or 3.5% of total final global energy consumption.1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are mined.

Charlar en Línea

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 The operating parameters like eccentric speed of jaw crusher, throw, power draw, closed Side Setting in cone crusher affect the energy efficiency of crushing plant. Stone properties may affect the performance of crusher. The crusher performance can be improved by applying different experimental, analytical and numerical techniques.

Charlar en Línea

Evaluation of Soil-Cutting and Plant-Crushing Performance of

2022.6.15 Severe plant entanglement and high power consumption are the main problems of the up-cut rotary blade during Cyperus esculentus harvesting. Optimization of the rotary blade edge can enhance the soil-cutting and plant-crushing performance. In this study, the double-eccentric circle method was used to design the edge curve of the

Charlar en Línea

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 Simulation results based on a crushing process in a coal-fired power plant demonstrate a potential of a daily energy cost saving of about 49.7% and energy saving of about 15.3% in a high-demand season weekday. ... Modelling of output and power consumption in vertical shaft impact crushers. Int J Miner Process (2008) S. Zhang et al.

Charlar en Línea

Aggregate Production Optimization in a Stone-Crushing Plant

2020.2.8 Crushing plants operate under unforgiving conditions and in most cases involve very ... (1991) Prediction of power consumption and product size in cone crushing. Miner Eng 4:1243–1256 ... Optimized compressive crushing with respect to energy consumption, pressure and multiple product yield. In: 12th Europan Symposium ...

Charlar en Línea

Complete Lecture about Crushers in Cement Industry

The practical index for power consumption for crushing medium hard lime stone amounts from 0.3-0.6 kWh/cuter of crusher feed [39]. ... Fig. 3.28. shows a two-stage crushing plant for pri mary and secondary crushing, equipped with high capacity double rotor hammer crushers (Orenstein and Koppel AG, Ennigerloh, W. Germany).

Charlar en Línea

ENERGY EFFICIENCY IN COMMINUTION -GETTING MORE FROM THE CRUSHING

2020.1.13 crushing plant, the secondary crush er provides a feed to the third crushing stage at d 80 = 35 mm and the tertiary crusher(s ) provide a feed, having d 80 = 8–9 mm, for milling in a closed circuit.

Charlar en Línea

Crushing Screening - Market Seeing Renewed Focus on

As per the projections for FY 2021-22, the scenario is positive with the expected demand growth of at least 15% y-o-y for new crushing and screening plants. The average capacity demand for semi-mobile plants will be in the range of 200 to 300 tph; for track units it will be 200 to 250 tph; while the stationary plants will see demand changing ...

Charlar en Línea

Crushing, Screening Conveying - 911 Metallurgist

The specific energy consumption at the motor input can be predicted using Bond's equation: E = 10 × CWi × (P80 – ½ - F80 –½). where CWi is your work index, F80 is the 80% passing size of the feed measured in µm, and P80 is the 80% passing size of the product measured in µm. E is the specific energy in kWh/tonne. Very important -- there

Charlar en Línea

Energy-Efficient Technologies in Cement Grinding

2016.10.5 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Charlar en Línea

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING PLANT

copper concentrates has never been attained since plant commissioning. The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain. The major hypotheses of this research are that performance in a crushing plant is adversely influenced by moderate and discrete changes in the

Charlar en Línea

Mathematical modeling of a vertical shaft impact crusher using

2017.9.1 Barmac crushers replaced roller crushers in the final crushing stage of a nepheline syenite processing plant, allowing feeding with a coarser feed, at similar circuit capacity, greater ease of operation, smaller space requirement, lower energy consumption and less demand for maintenance with slightly higher generation of fines (i.e. material

Charlar en Línea

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL

Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement. Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identification INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, its

Charlar en Línea

Case Study: Bagasse Cogeneration Development in Thailand’s

- 1 Power Plant : 32 MW - Crushing Capacity: 87.5 k TCD - Refinery Capacity: 2.6 k Ton/Day - Pulp Paper: 60 k Ton/Day Thai Sugar Business ... Crushing Remelting Steam Consumption, ton/hr 550 160 Power Consumption,

Charlar en Línea

Crusher Operating Costs: How to Optimize and Reduce - 911

2016.1.10 It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest. The power consumption of a machine or installation is usually expressed in kw.-hours per ton as being the most convenient method.

Charlar en Línea

Power draw of the crusher when varying the speed and CSS,

These design parameters were varied to analyse deformation and stress distribution during crushing. Design of experiment techniques was used to determine the optimal design parameters ...

Charlar en Línea

(PDF) Applied Calibration and Validation Method of Dynamic

2021.8.25 Applied Calibration and Validation Method of Dynamic Process Simulation for Crushing Plants. August 2021; Minerals ... The estimation of the mass flow using conveyor belt power consumption allows ...

Charlar en Línea

Power Consumption Comparison between conventional and Two

2023.3.4 A traditional Sugar Mill, which currently runs at 6000 TCD, has been identified as a primary model for this upgrade. By up gradation to 2-roller mills, instead of 4-roller or 6-roller mills, this ...

Charlar en Línea

>> Next:Tipos De Trituradoras Para Diferentes Materiales

- de alta eficiencia y un buen rendimiento de la mina cono de trituración de la máquina

- experimento de flotacion

- manualidades con piedras de rio

- clasificador en espiral para minerales raros de bajo grado

- planta trituracion trituradora

- montaje de una chancadora LM

- Partes de un trituradoras de martillo

- mineral de hierro de beneficio proceso de vietnam

- estado de los equipos de grava arte canteras

- Máquina Trituradora Defn

- procesamiento y refinación del mineral de carbón y foss

- trituradora de piedra para el mineral de hierro en indonesia

- triturador de cobre en colombia

- mineral de hierro para la venta por los fabricantes

- precio unitario de nakayama trituradora de mandíbula mc140p